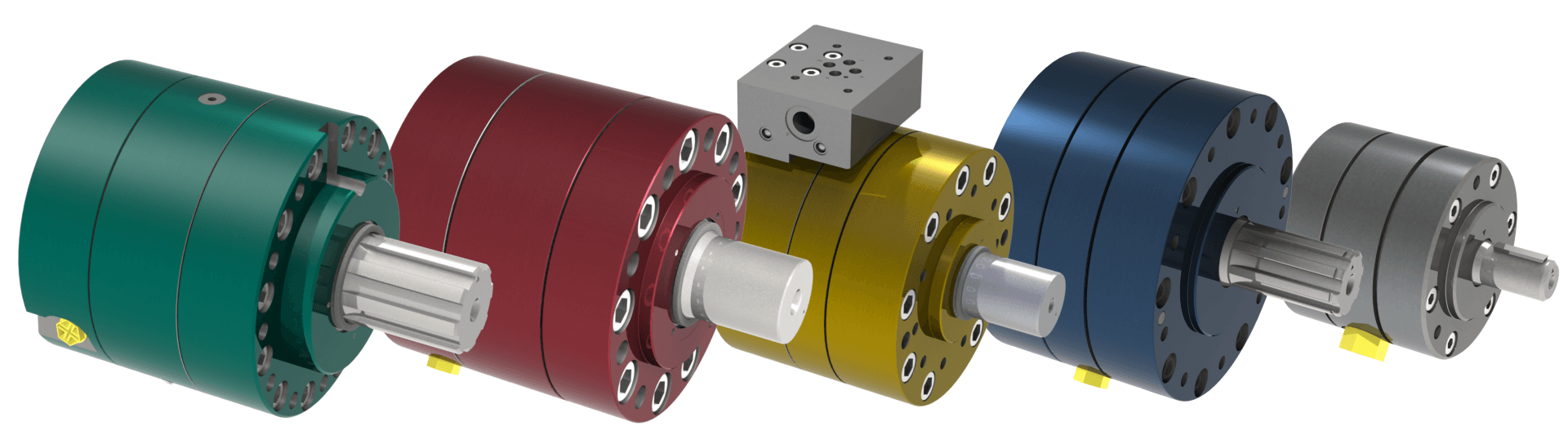

5 series of rotary cylinders and rotary actuators

SHM Südhydraulik swivel actuators from HOMRICH are characterized by:

• High efficiency - the power is transferred to torque without mechanical translation

• high positioning accuracy (comparable to electric servo motors)

• Space-saving design with high torque and rotational speeds at the same time

• Very little wear, since the moving parts are reduced to a minimum

• Extremely long service life and maintenance intervals thanks to the robust design and high-quality materials

• explosion-proof, thanks to encapsulated construction

• Low heat generation through continuous oil exchange

• No electromagnetic fields - drive completely without electrical cables or components

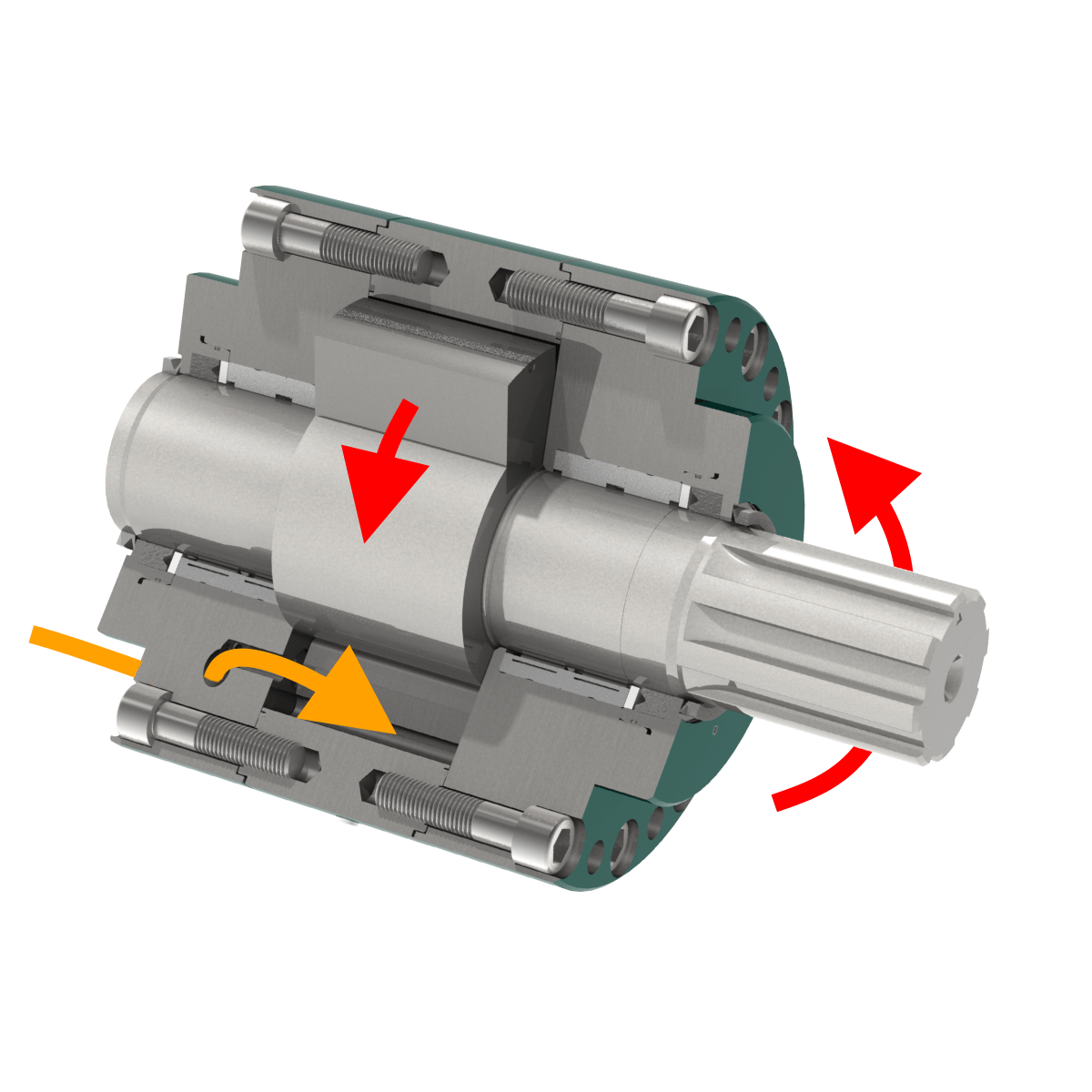

How does a rotary piston cylinder work?

An annular space is formed between a hollow cylinder and a shaft. By means of a piston, which is firmly connected to the shaft, and a partition, which is attached to the housing, this circular space is divided into two working spaces. If pressure is applied to one of the workrooms, a torque is created - the rotary cylinder executes the desired rotary movement. The force generated in this way is transmitted immediately.

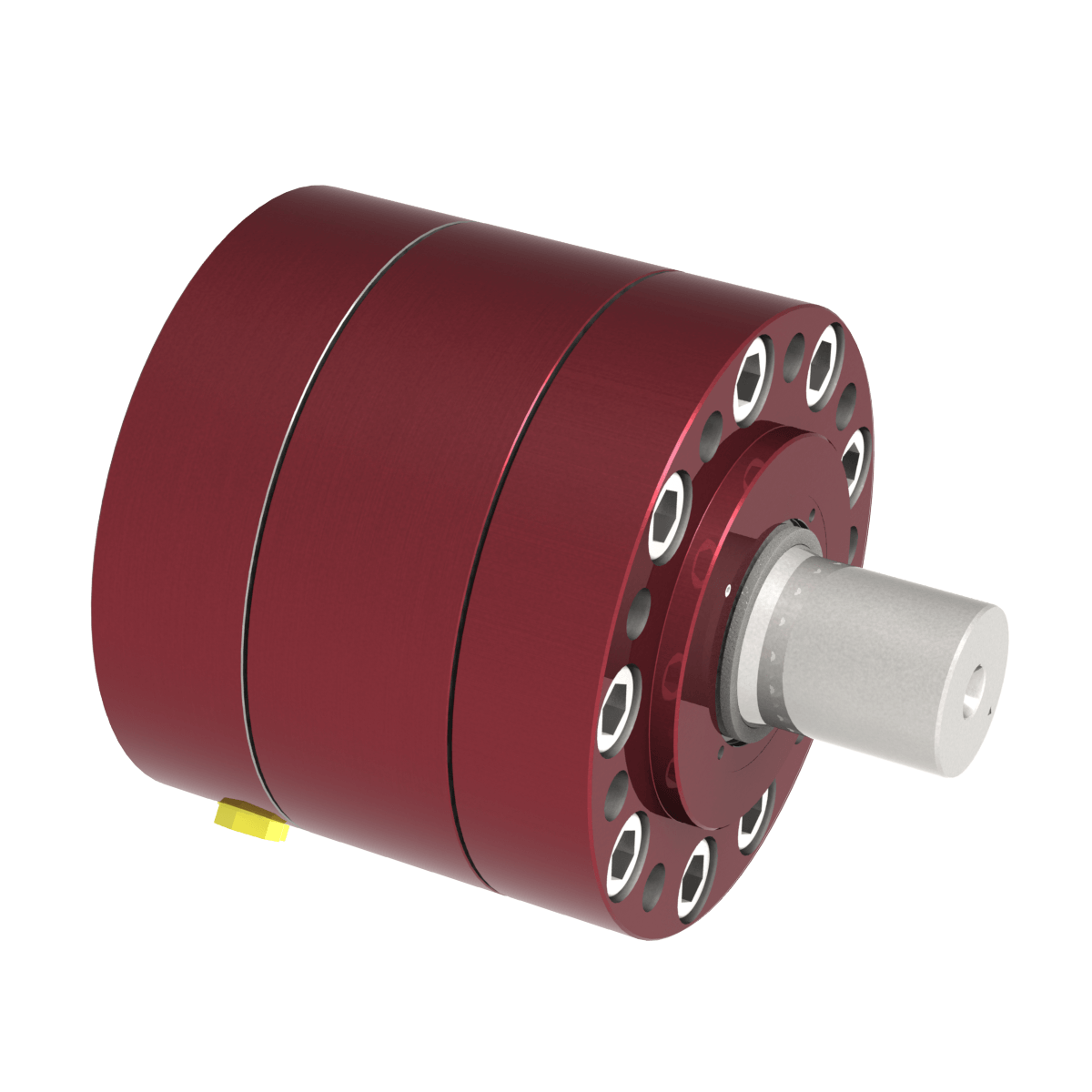

Hydraulic part-turn actuators from Südhydraulik

A hydraulic part-turn actuator stands for a unique combination of power, precision and maximum flexibility. With part-turn actuators from SÜDHYDRAULIK, a brand of Homrich Maschinenbau GmbH, you are placing your trust in a world-leading manufacturer of high-performance part-turn actuators. We will be happy to advise you on how you can design your task efficiently and reliably with a hydraulic drive solution from us.

Where are hydraulic part-turn actuators used?

As a powerful drive solution, hydraulic part-turn actuators are used in a wide variety of industries and areas - wherever powerful and precise swivel and rotary movements with a high torque and reliability play a role. These include applications in industrial sectors such as:

- Machine and plant construction

- Automotive and commercial vehicle industry

- Chemical/pharmaceutical industry

- Steelworks, mining

- Food and confectionery industry

- On- and offshore technology and shipbuilding

In addition to swivel and rotary movements, you can also realise combined linear movement sequences with a hydraulic rotary actuator from SÜDHYDRAULIK. Whether opening or closing, tilting and indexing, bending or swivelling of assemblies or components, a hydraulic part-turn actuator offers you new possibilities in solving your drive tasks and motion sequences.

If you have any further specific questions about our drives, we will be happy to advise you.

Typical areas of application for the quarter turn actuator

In recent years, the areas of application for hydraulic part-turn actuators have developed in two different directions in which their special characteristics are exploited:

1. high-torque actuators

- Here, the focus is on the high torque that our quarter-turn actuators of the LDK and HDK series deliver: rotary movements of up to 270° can be realised with maximum efficiency and minimum space requirements. As a rule, the most important thing is a uniform, powerful movement; the slewing speed is often secondary. If required, the torque can even be doubled with a reduced swivel angle. Typical applications are control or actuating drives in shipbuilding, the swivelling of heavy moulds in plastics processing or actuating drives in heavy machinery.

2.

high-frequency drives

- In these applications, the most important thing is a high dynamic and switching movement. This can be optimally realised with the drives of our SP and HSR series. Depending on the version and size, angular speeds of up to xx °/sec and load changes of 10 Hz and more are possible - requirements that are common, for example, on test benches in chassis construction.

Are you looking for the right solution for your drive task? We will be happy to support you in the integration of our drives. You can download the technical data sheets and 3D models for all series models here on our website. Our colleagues in the technical department will be happy to answer any further questions you may have.

Your advantages when using our part-turn actuators:

With a part-turn actuator from SÜDHYDRAULIK you benefit from many advantages:

- high efficiency for a sustainable and efficient drive solution

- Robust, long-lasting construction with low maintenance and wear

- high torque with compact design

- wide range of models with many finely graduated standard sizes

- standard design with variants for easy integration into your construction

- Standard or special swivel angles up to 270°.

- Application-specific special solutions, e.g. seawater-resistant materials and coatings or food-compatible specifications for HFC operation

Contact us now for your innovative quarter-turn actuator

Would you like to find out more about part-turn and rotary actuators? Our team looks forward

to your enquiry and will be happy to support you with your tasks.